Operational stability test for vehicle seats combines high-performance hydraulics and controltechnology

Servohydraulic lifecycle tests are also the current industry standard for automobile componentsthat are used far beyond safety-related structural elements. The challenge for suchtesting facilities lies in bringing together widely varying technologies at the highest level. Withthis, the users particularly place high demands on the test cylinder and realtime control. Thedevelopment service provider, IAV GmbH, from Gifhorn has taken such a servohydraulic seattest stand into operation, which is controlled by a digital servocontroller from FCS Control-Systems and is powered by a test cylinder from Hänchen Hydraulik.

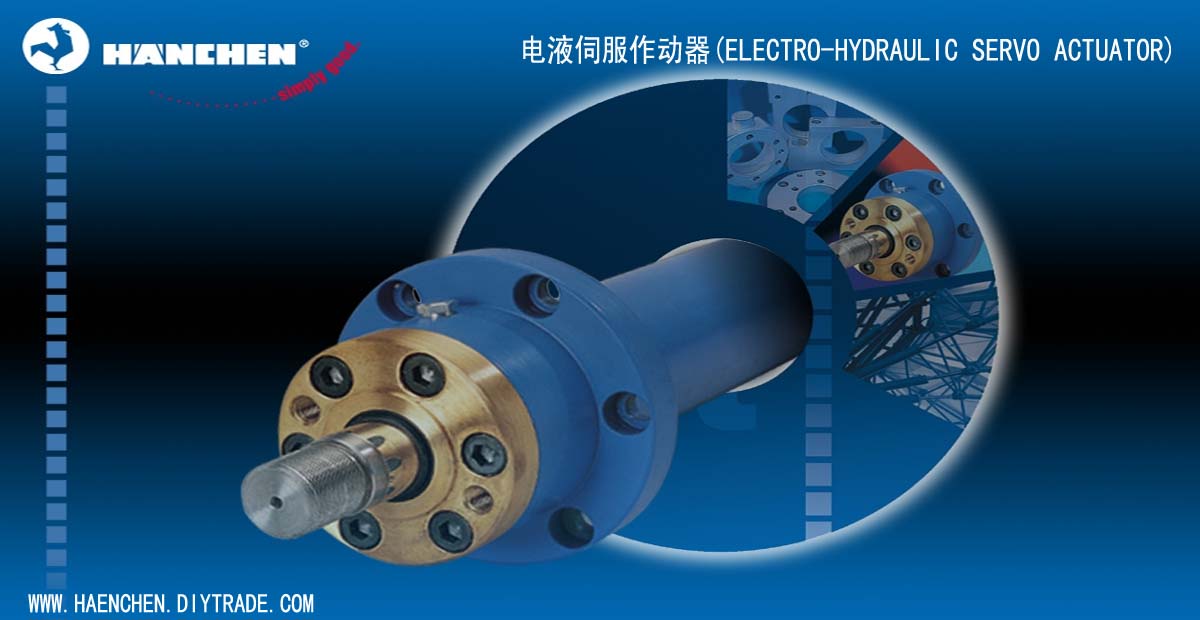

The testing takes place with a Hänchen test cylinderof the type series 328 as an actuator. In thisconstant velocity cylinder, the patented floatingannular gap seal by Hänchen with the brand name,Servofloat, is used. With this, a steel liner followsthe radial deflection of the piston rod with a sealinggap of a few 1/100 mm over practically the entirepressure range. This type series only distinguishesitself through its somewhat higher sensitivity to lateralforces from a cylinder with a hydrostatically supportedpiston rod guide, but provides a cost benefitof around 30%. After all, only the leak oil sealscause a negligible minimum amount of friction.Through their negligible friction, cylinders inServofloat quality offer the highest positioning andrepetition precision, are stick-slip-free and suited toextremely slow and fast movements.

In thisconstant velocity cylinder, the patented floatingannular gap seal by Hänchen with the brand name,Servofloat, is used. With this, a steel liner followsthe radial deflection of the piston rod with a sealinggap of a few 1/100 mm over practically the entirepressure range. This type series only distinguishesitself through its somewhat higher sensitivity to lateralforces from a cylinder with a hydrostatically supportedpiston rod guide, but provides a cost benefitof around 30%. After all, only the leak oil sealscause a negligible minimum amount of friction.Through their negligible friction, cylinders inServofloat quality offer the highest positioning andrepetition precision, are stick-slip-free and suited toextremely slow and fast movements.

Thus, the seat test stand works in standard operationwith a test load of up to 28 kN, with a frequencyof maximum 20 Hz, a dynamic lift of up to 35mm, a speed of up to 1.3 m/s and acceleration ofup to 50 m/s_. Nevertheless, it possesses highsafety reserves that ensure optimum operation: Thetechnically admissible maximum speed, for example,is 4 m/s. This testing facility not only tests completeseat structures, but also adjustment equipment,backrests, lordosis supports, springs, railsand covering components. Furthermore, foam componentscan be tested for tears and breakages andthe intrusion of a part into another material, which isderived from the hysteresis shift.

with a frequencyof maximum 20 Hz, a dynamic lift of up to 35mm, a speed of up to 1.3 m/s and acceleration ofup to 50 m/s_. Nevertheless, it possesses highsafety reserves that ensure optimum operation: Thetechnically admissible maximum speed, for example,is 4 m/s. This testing facility not only tests completeseat structures, but also adjustment equipment,backrests, lordosis supports, springs, railsand covering components. Furthermore, foam componentscan be tested for tears and breakages andthe intrusion of a part into another material, which isderived from the hysteresis shift.

Upon starting the system, a hydrodynamic oil flow is built up in the annular gap seal via the cylinderchambers, so that the annular gap seal moves radially around the piston road without touching metal,“floating” and in a self-centring manner. The escaping leak oil is fed back into the fluid loop without pressure,through a collective connection. The lack of a tangential seal that is subjected to pressure minimisesthe static and dynamic friction in the cylinder. Because no hydrodynamic lubricant film is requiredthrough the relative movement of the gliding partners, a stick-slip-free movement can take place, evenin the range of smallest amplitudes and speeds. The annular gap seal only has a pressure reductionfunction with the slightest leak, so that the piston rod is guided with friction-optimised bands.Nevertheless, even a cylinder with a floating annular gap seal can absorb certain transverse forces. Inconcrete application, 1.2 kN is admissible, which is absorbed by plastic guide bands. The 328 seriesfurthermore has dry-running operational features that additionally increase operating reliability throughthe piston and bearing surfaces that are coated with specialised bronze.

is built up in the annular gap seal via the cylinderchambers, so that the annular gap seal moves radially around the piston road without touching metal,“floating” and in a self-centring manner. The escaping leak oil is fed back into the fluid loop without pressure,through a collective connection. The lack of a tangential seal that is subjected to pressure minimisesthe static and dynamic friction in the cylinder. Because no hydrodynamic lubricant film is requiredthrough the relative movement of the gliding partners, a stick-slip-free movement can take place, evenin the range of smallest amplitudes and speeds. The annular gap seal only has a pressure reductionfunction with the slightest leak, so that the piston rod is guided with friction-optimised bands.Nevertheless, even a cylinder with a floating annular gap seal can absorb certain transverse forces. Inconcrete application, 1.2 kN is admissible, which is absorbed by plastic guide bands. The 328 seriesfurthermore has dry-running operational features that additionally increase operating reliability throughthe piston and bearing surfaces that are coated with specialised bronze.

The oil supply is of crucial importance to the effectiveness of the floating annular gap seal. The cleanerthe oil is, the more reliably the system works. If the particles in the oil are not larger than _ of the smallestgap height, the split rings do not wear. Therefore, Hänchen recommends purity class 13/11 accordingto ISO 4406. In the testing and inspection systems, hydraulic cylinders with the floating annulargap seal offer a true high-performance cylinder with a distinct price advantage over cylinders with ahydrostatically supported piston rod guide. Hänchen Hydraulik also offers these high-end cylinders,which can compensate a maximum possible amount of transverse force. As the start-up friction is omitted,the stick-slip-free operation is also ensured with the lowest piston speeds. Only through the pressure-free stripping away seal elements is a low residual friction available, which is constant over the entirepressure range. Through this, the complex and workplace-contaminating suction removal of leak oil isavoided.

works. If the particles in the oil are not larger than _ of the smallestgap height, the split rings do not wear. Therefore, Hänchen recommends purity class 13/11 accordingto ISO 4406. In the testing and inspection systems, hydraulic cylinders with the floating annulargap seal offer a true high-performance cylinder with a distinct price advantage over cylinders with ahydrostatically supported piston rod guide. Hänchen Hydraulik also offers these high-end cylinders,which can compensate a maximum possible amount of transverse force. As the start-up friction is omitted,the stick-slip-free operation is also ensured with the lowest piston speeds. Only through the pressure-free stripping away seal elements is a low residual friction available, which is constant over the entirepressure range. Through this, the complex and workplace-contaminating suction removal of leak oil isavoided.

Through the chassis mounted directly on the cylinder for the servo valve, a compact servocylindersystem is created for the highest dynamic requirements. The catalogue cylinder selected by FCS andused by IAV has a chassis for every proportional servo valve and each of one membrane and bubblestorage for compensating the pulsation of the pump and other disturbances in the fluid flow. Already inseries production, the cylinders contain specifically selected low-backlash hinge bearing and an emergencyfinal position damper, in this application with 10 mm. Two inductive position sensors integrated inthe cylinder, as well as an attached acceleration recorder and load cell provide the control of the necessarydata.

The decisive point with this is the Z-axis moved by the cylinder, which the FCS digital controller,“ SmarTEST One“ controls through a control loop that is addressed through direction and acceleration.In contrast, the Y-axis is regulated by a crank drive. It triggers overlaid translatory sinusoidal movement.“ SmarTEST One” is a universal digital controller that can be used in stand-alone operation without a PCand with its own 20 GB hard disk for programmes, test cycles and protocols. Each unit can address upto four channels concurrently and coordinated with one another. The larger FCS systems control morethan 300 channels. Most of the functions can be set through an ergonomic single-knob control and adisplay in VGA format, a PC keyboard can be easily connected. The controller can automatically identifyand calibrate transmitters. At the core of smallest system by FCS is the SmarTest Control Unit, whichhas already proven itself more than 1000 times in products of the Dutch controls specialist. This processorsystem distinguishes itself, among other things, through a series of safety functions, such as independentself-tests, fault-protected design and independent test of all entries through user-defined specifications.In addition to conventional functions, “SmarTESTOne” enables the editing of the wave form.Signal processing and preparation takes place through the “FasTEST Manager” software by FCS. Itgenerates load time sequence plots and adapts these through a high-capacity iteration process. Withthis, both analogue and digital data are processed, as required. Thus, despite the 20 Hz of the actuator,highly dynamic loads beyond derived sinusoidal functions can be simulated, as they occur on a gravelpiste, for example. This places just as high demands on the process pulse of the controller as it does onthe hydraulic cylinder.

Thus, the IAV test system can drive the majority of the test cycles prescribed by the automobile industry.The second axis ensures that the dummy slides around on the seat in a realistic manner, so that thetest stand also simulates fabric wear through transverse movements. Up to three backrest or seat frameswith a backside/seat back dummy have space on the test rig and can therefore be tested at thesame time. The actual test know-how is brought into the system by the IAV: the programming of realistictest processes, the interplay of the components and the advisory of the user. Particularly when weakareas are shown through tears, breakages, wear or settlement, the specialists provide advice regardingdefect elimination. With the test stand, the companies offer an equally high-performance and economicaltest facility, in order to test components under conditions that are as realistic as possible. Accordingto Team Leader, Dipl.-Ing Andreas Hesse, the crucial point for the collaboration is “that FCS andHänchen work together in a very flexible and committed manner and that both companies carry outgood quality realisation, even in smaller projects.”

Servohydraulic lifecycle tests are also the current industry standard for automobile componentsthat are used far beyond safety-related structural elements. The challenge for suchtesting facilities lies in bringing together widely varying technologies at the highest level. Withthis, the users particularly place high demands on the test cylinder and realtime control. Thedevelopment service provider, IAV GmbH, from Gifhorn has taken such a servohydraulic seattest stand into operation, which is controlled by a digital servocontroller from FCS Control-Systems and is powered by a test cylinder from Hänchen Hydraulik.

The testing takes place with a Hänchen test cylinderof the type series 328 as an actuator.

In thisconstant velocity cylinder, the patented floatingannular gap seal by Hänchen with the brand name,Servofloat, is used. With this, a steel liner followsthe radial deflection of the piston rod with a sealinggap of a few 1/100 mm over practically the entirepressure range. This type series only distinguishesitself through its somewhat higher sensitivity to lateralforces from a cylinder with a hydrostatically supportedpiston rod guide, but provides a cost benefitof around 30%. After all, only the leak oil sealscause a negligible minimum amount of friction.Through their negligible friction, cylinders inServofloat quality offer the highest positioning andrepetition precision, are stick-slip-free and suited toextremely slow and fast movements.

In thisconstant velocity cylinder, the patented floatingannular gap seal by Hänchen with the brand name,Servofloat, is used. With this, a steel liner followsthe radial deflection of the piston rod with a sealinggap of a few 1/100 mm over practically the entirepressure range. This type series only distinguishesitself through its somewhat higher sensitivity to lateralforces from a cylinder with a hydrostatically supportedpiston rod guide, but provides a cost benefitof around 30%. After all, only the leak oil sealscause a negligible minimum amount of friction.Through their negligible friction, cylinders inServofloat quality offer the highest positioning andrepetition precision, are stick-slip-free and suited toextremely slow and fast movements.Thus, the seat test stand works in standard operationwith a test load of up to 28 kN,

with a frequencyof maximum 20 Hz, a dynamic lift of up to 35mm, a speed of up to 1.3 m/s and acceleration ofup to 50 m/s_. Nevertheless, it possesses highsafety reserves that ensure optimum operation: Thetechnically admissible maximum speed, for example,is 4 m/s. This testing facility not only tests completeseat structures, but also adjustment equipment,backrests, lordosis supports, springs, railsand covering components. Furthermore, foam componentscan be tested for tears and breakages andthe intrusion of a part into another material, which isderived from the hysteresis shift.

with a frequencyof maximum 20 Hz, a dynamic lift of up to 35mm, a speed of up to 1.3 m/s and acceleration ofup to 50 m/s_. Nevertheless, it possesses highsafety reserves that ensure optimum operation: Thetechnically admissible maximum speed, for example,is 4 m/s. This testing facility not only tests completeseat structures, but also adjustment equipment,backrests, lordosis supports, springs, railsand covering components. Furthermore, foam componentscan be tested for tears and breakages andthe intrusion of a part into another material, which isderived from the hysteresis shift.Upon starting the system, a hydrodynamic oil flow

is built up in the annular gap seal via the cylinderchambers, so that the annular gap seal moves radially around the piston road without touching metal,“floating” and in a self-centring manner. The escaping leak oil is fed back into the fluid loop without pressure,through a collective connection. The lack of a tangential seal that is subjected to pressure minimisesthe static and dynamic friction in the cylinder. Because no hydrodynamic lubricant film is requiredthrough the relative movement of the gliding partners, a stick-slip-free movement can take place, evenin the range of smallest amplitudes and speeds. The annular gap seal only has a pressure reductionfunction with the slightest leak, so that the piston rod is guided with friction-optimised bands.Nevertheless, even a cylinder with a floating annular gap seal can absorb certain transverse forces. Inconcrete application, 1.2 kN is admissible, which is absorbed by plastic guide bands. The 328 seriesfurthermore has dry-running operational features that additionally increase operating reliability throughthe piston and bearing surfaces that are coated with specialised bronze.

is built up in the annular gap seal via the cylinderchambers, so that the annular gap seal moves radially around the piston road without touching metal,“floating” and in a self-centring manner. The escaping leak oil is fed back into the fluid loop without pressure,through a collective connection. The lack of a tangential seal that is subjected to pressure minimisesthe static and dynamic friction in the cylinder. Because no hydrodynamic lubricant film is requiredthrough the relative movement of the gliding partners, a stick-slip-free movement can take place, evenin the range of smallest amplitudes and speeds. The annular gap seal only has a pressure reductionfunction with the slightest leak, so that the piston rod is guided with friction-optimised bands.Nevertheless, even a cylinder with a floating annular gap seal can absorb certain transverse forces. Inconcrete application, 1.2 kN is admissible, which is absorbed by plastic guide bands. The 328 seriesfurthermore has dry-running operational features that additionally increase operating reliability throughthe piston and bearing surfaces that are coated with specialised bronze.The oil supply is of crucial importance to the effectiveness of the floating annular gap seal. The cleanerthe oil is, the more reliably the system

works. If the particles in the oil are not larger than _ of the smallestgap height, the split rings do not wear. Therefore, Hänchen recommends purity class 13/11 accordingto ISO 4406. In the testing and inspection systems, hydraulic cylinders with the floating annulargap seal offer a true high-performance cylinder with a distinct price advantage over cylinders with ahydrostatically supported piston rod guide. Hänchen Hydraulik also offers these high-end cylinders,which can compensate a maximum possible amount of transverse force. As the start-up friction is omitted,the stick-slip-free operation is also ensured with the lowest piston speeds. Only through the pressure-free stripping away seal elements is a low residual friction available, which is constant over the entirepressure range. Through this, the complex and workplace-contaminating suction removal of leak oil isavoided.

works. If the particles in the oil are not larger than _ of the smallestgap height, the split rings do not wear. Therefore, Hänchen recommends purity class 13/11 accordingto ISO 4406. In the testing and inspection systems, hydraulic cylinders with the floating annulargap seal offer a true high-performance cylinder with a distinct price advantage over cylinders with ahydrostatically supported piston rod guide. Hänchen Hydraulik also offers these high-end cylinders,which can compensate a maximum possible amount of transverse force. As the start-up friction is omitted,the stick-slip-free operation is also ensured with the lowest piston speeds. Only through the pressure-free stripping away seal elements is a low residual friction available, which is constant over the entirepressure range. Through this, the complex and workplace-contaminating suction removal of leak oil isavoided.Through the chassis mounted directly on the cylinder for the servo valve, a compact servocylindersystem is created for the highest dynamic requirements. The catalogue cylinder selected by FCS andused by IAV has a chassis for every proportional servo valve and each of one membrane and bubblestorage for compensating the pulsation of the pump and other disturbances in the fluid flow. Already inseries production, the cylinders contain specifically selected low-backlash hinge bearing and an emergencyfinal position damper, in this application with 10 mm. Two inductive position sensors integrated inthe cylinder, as well as an attached acceleration recorder and load cell provide the control of the necessarydata.

The decisive point with this is the Z-axis moved by the cylinder, which the FCS digital controller,“ SmarTEST One“ controls through a control loop that is addressed through direction and acceleration.In contrast, the Y-axis is regulated by a crank drive. It triggers overlaid translatory sinusoidal movement.“ SmarTEST One” is a universal digital controller that can be used in stand-alone operation without a PCand with its own 20 GB hard disk for programmes, test cycles and protocols. Each unit can address upto four channels concurrently and coordinated with one another. The larger FCS systems control morethan 300 channels. Most of the functions can be set through an ergonomic single-knob control and adisplay in VGA format, a PC keyboard can be easily connected. The controller can automatically identifyand calibrate transmitters. At the core of smallest system by FCS is the SmarTest Control Unit, whichhas already proven itself more than 1000 times in products of the Dutch controls specialist. This processorsystem distinguishes itself, among other things, through a series of safety functions, such as independentself-tests, fault-protected design and independent test of all entries through user-defined specifications.In addition to conventional functions, “SmarTESTOne” enables the editing of the wave form.Signal processing and preparation takes place through the “FasTEST Manager” software by FCS. Itgenerates load time sequence plots and adapts these through a high-capacity iteration process. Withthis, both analogue and digital data are processed, as required. Thus, despite the 20 Hz of the actuator,highly dynamic loads beyond derived sinusoidal functions can be simulated, as they occur on a gravelpiste, for example. This places just as high demands on the process pulse of the controller as it does onthe hydraulic cylinder.

Thus, the IAV test system can drive the majority of the test cycles prescribed by the automobile industry.The second axis ensures that the dummy slides around on the seat in a realistic manner, so that thetest stand also simulates fabric wear through transverse movements. Up to three backrest or seat frameswith a backside/seat back dummy have space on the test rig and can therefore be tested at thesame time. The actual test know-how is brought into the system by the IAV: the programming of realistictest processes, the interplay of the components and the advisory of the user. Particularly when weakareas are shown through tears, breakages, wear or settlement, the specialists provide advice regardingdefect elimination. With the test stand, the companies offer an equally high-performance and economicaltest facility, in order to test components under conditions that are as realistic as possible. Accordingto Team Leader, Dipl.-Ing Andreas Hesse, the crucial point for the collaboration is “that FCS andHänchen work together in a very flexible and committed manner and that both companies carry outgood quality realisation, even in smaller projects.”

没有评论:

发表评论